Sustainability — the long-term protection of the Earth’s resources — is a concept that drives manufacturing, distribution, marketing and other business decisions.Investors expect it. Customers demand it. But to ingrain sustainability thinking in day-to-day operations, employees must understand how such thinking can be incorporated into their jobs.

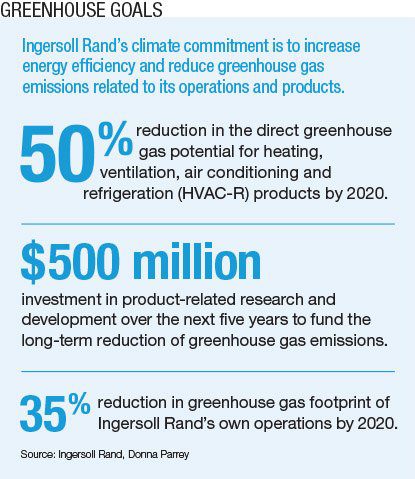

How can the organization create greener products? How can it reduce waste? Reduce energy consumption? Lower emissions? Building this knowledge in employees is a challenge for learning leaders and the prime reason Ingersoll Rand create its Design for Sustainability, or DfS, training. Along the way, it created authentic employee engagement and aligned employees’ strengths to the company’s mission.

The Problem at Hand

Sustainability is a hallmark of Ingersoll Rand, aglobal,diversified industrial company. CEO Mike Lamach’s Path to Premier Performance defines what success looks like and connects that vision to values and core competencies. On the Path to Premier Performance, three concepts intersect: growth through innovation, emerging markets and services; operational excellence; and a progressive, diverse and inclusive culture.

Ingersoll Rand formed the Center for Energy Efficiency & Sustainability in 2010 as the first strategic step to instill sustainability into the company’s culture so every function understood its role in sustainability. Gretchen Digby, director of global sustainability programs for the center, wanted to create an in-house learning program for the company’s 40,000 employees to develop a broad understanding of sustainability and how it affects the organization.

Employees, however, wanted more. “Product development team members wanted their learning to represent an achievement that would be recognized externally as well as within the company,” Digby said. So she approached UL, a safety consulting and certification firm headquartered in Northbrook, Illinois, and asked if the company would consider certifying employee learning around sustainable design.

Because UL has offices in dozens of countries and has a well-respected brand — the company has certified everything from air compressor systems to industrial hammers, as well as personnel — it seemed logical to apply a similar process to a learning initiative. “While Ingersoll Rand had not previously worked with UL, I knew that environment is one of their six key strategic businesses and that they offer training on sustainability and environmental standards, so it was a perfect fit,” Digby said.

Catherine Sheehy, program manager at UL Environment, said one of the benefits in offering a certificate in Design for Sustainability training is it helps to embed sustainability thinking into Ingersoll Rand’s productdevelopment process. Ultimately, that can bring more sustainable products to market, and on a larger scale, it helps to make the world a healthier, safer place. “It creates behavior and culture change,” she said.

Ingersoll Rand’s partnership with UL resulted in a first-of-its-kind Design for Sustainability certificate program, which verifies participants learned to:

- Advocate for sustainability with product design teams.

- Analyze and articulate market-specific value propositions of sustainability.

- Expand risk-and-opportunity assessments to include sustainability.

- Incorporate sustainability-related attributes into all product design.

- Understand the trade-offs and opportunities during product design.

The Learning Solution

The next strategic step was to segment Ingersoll Rand employees into general, technical and leadership populations to determine their level of sustainability knowledge and create a learning plan to close the gap and increase awareness, capability and expertise.

Digby said the learning plan quickly revealed that product development teams needed to become experts fast, so they had to determine what the group needed to know to design differently. The product development team realized it needed representation from engineering, supply chain and other functions to influence product designs and create a truly integrated effort. So, the company developed the Design for Sustainability program in conjunction with Ingersoll Rand University.

IRU launched 10 years ago with a narrow focus on leadership development for high-potential employees. The focus has evolved to target business, leadership and strategic capabilities. “The DfS program is just one example of IRU blending internal software and a collaboration with external entities to create learning that delivers both impact and cost efficiency,” said Craig Mundy, Ingersoll Rand’s vice president of talent and organizational capability.

The course was marketed as a development opportunity. No approval is required, and it’s open to everyone, regardless of function. “It truly expands the employees’ base strength in sustainability which aligns with our enterprise mission,” Digby said. “Additionally, engagement was authentic because people felt more valued being offered this gift from the company — the opportunity to advance their capabilities/skillset.”

The sustainability program has two credential levels: silver and gold. The silver level has about six to seven hours of self-paced online learning and is geared toward those who want to understand why Ingersoll Randfocuses on design sustainability. The gold level takes about 10 to 11 hours of self-paced online learning. There are three 90-minute sessions conducted at scheduled times, led by a virtual instructor from UL Environment. Upon completion, the employee is invited to sit for the silver or gold exam, which is administered by UL.

The Multiplier Effect

The success of the program rollout can be attributed in large part to how well Ingersoll Rand involved its internal stakeholders in the design and implementation. Sheehy said the company identified process owners, subject-matter experts, learning professionals and others early on and used their feedback throughout course development and pilot.

The sustainability program launched last year, concentrating on design and manufacturing engineers, product managers, procurement leaders and others involved in product development. The 2014 goal was 240 participants. As of November 2014, 200 were progressing through the program. In its pilot, 100 percent of participants were satisfied, with 45 percent significantly satisfied.

As new products launch following the DfS learning and credentialing process, learning leaders will collect hard data such as new products using different materials to improve greenhouse gases or whether using a different material reduced weight, thereby reducing freight cost and increasing fuel efficiency. Ingersoll Rand is also seeking to affect enterprise values such as employee satisfaction, employee engagement and to enhance its talent profile.

Sustainability is also within IRU’s strategic capabilities, and there is a direct connection with the board of directors. Several times per year, a rotating group of executives review delivery and effect of sustainability numbers.

The certificate was exclusive to Ingersoll Rand in 2014, but now UL Environment can consider developing similar training programs with other companies in the Ingersoll Rand industry group.

For Ingersoll Rand, sustainability is four-fold:

- To local employees: Raises awareness and exposure to environmental concepts.

- To the organization: Learning spreads as more Ingersoll Rand cohorts go through the process.

- To the customers: Greener products and higher efficiency resonates with them.

- To the market: Employees build better products, reduce energy consumption, and engage in environmentally friendly thinking to position the company as a global leader.

Ingersoll Rand is not alone in its effort. Consumer health company Johnson & Johnson Services Inc.’s Earthwards program recognizes products that demonstrate performance standards. Al Iannuzzi, the company’s senior director of environment, health, safety and sustainability product stewardship and author of “Greener Products: the Making and Marketing of Sustainable Brands,” said it’s critical that companies reflect sustainability in their thinking and design efforts. “This kind of focus can have a long-term positive impact on the protection of resources which are becoming scarcer as the middle class rapidly grows in developingnations.”

Green-Colored Glasses

This year, Ingersoll Rand will expand Design for Sustainability into moreareas, maintain the firm’s collaboration with UL, refresh content, and stay on top of external news. It also wants to build deeper sustainability conversations with other partners.

Mundy said chief learning officers who have to introduce a new learning and development initiative should:

- Be thoughtful about the process at the outset. Conduct a pilot program with a group that is likely to receive the most up-front impact. Ingersoll Rand started with a segment from its product development teams, including manufacturing, engineering and product management employees.

- Get feedback and make adjustments.

- Consider blended-learning software. Determine the best fit for online learning, virtual instructor-led training and interactive instructor-led presentations. Then get feedback on the mix.

For any sustainability-learning program to have a great effect, it’s critical to establish the vision. “Create a movement, create a call to action help people understand the impact sustainability has on the world,” Mundy said.